Condensation and the Falling Film Evaporator

Most Condensation that Occurs during Processing with the Falling Film Evaporator Happens within the Pump

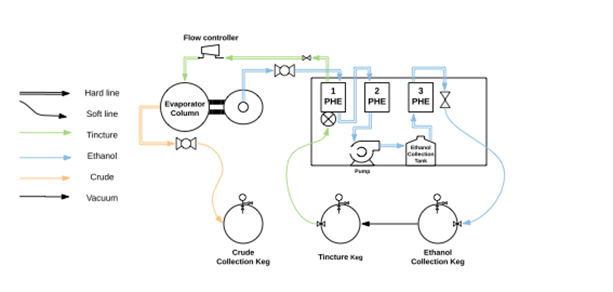

On a very basic level, the function of the Falling Film Evaporator (FFE) can be summed up as follows:

- The operator inputs a cannabinoid and ethanol solution (tincture),

- The FFE evaporates the bulk of the solvent (ethanol),

- Outputting separately the crude extract, and the condensed solvent.

The purpose of the Plate Heat Exchangers (or PHE), as their name implies, is to exchange heat. The PHEs utilize an outside chiller to circulate a cold propylene glycol and water mix. This cools the hot ethanol vapor to cause it to condense back to a liquid.

While the PHEs do condense some of the ethanol back to a liquid, perhaps a bit counter intuitively, most of this condensation occurs within the pump of the system. To explain this further we’ll describe the approximate function of each of the three PHEs as well as the pump.

When looking at the FFE (moving from left to right in the diagram above), the first Plate Heat Exchanger (PHE) is not serviced by the outside chiller, and so very little condensation occurs here, but this stage does begin to cool the ethanol vapor if you are inputting cold tincture (we’ll talk more about this initial stage of the process in another Did You Know? article to come so watch out for that one.)

The second PH—out of all the heat exchangers—condenses the vapor most significantly and is also serviced by the outside chiller. The ethanol vapor / liquid stream passes through the first PHE, then the second, before being pulled to the pump of the FFE system (see pump in diagram above under PHE #2).

Primarily due to a large shift in vacuum level and vapor pressure, when the ethanol vapor / liquid stream enters and encounters the pump, essentially all the remaining ethanol vapor is then condensed into a liquid.

The ethanol is then deposited into the primary ethanol collection tank. It then passes through the last, or third PHE which is also serviced by an outside chiller to ensure that no vapors are ejected from the system.

The condensed ethanol is then finally ejected from the system whereupon it may be reused at the beginning of the extraction process.